Injected aluminium cast iron

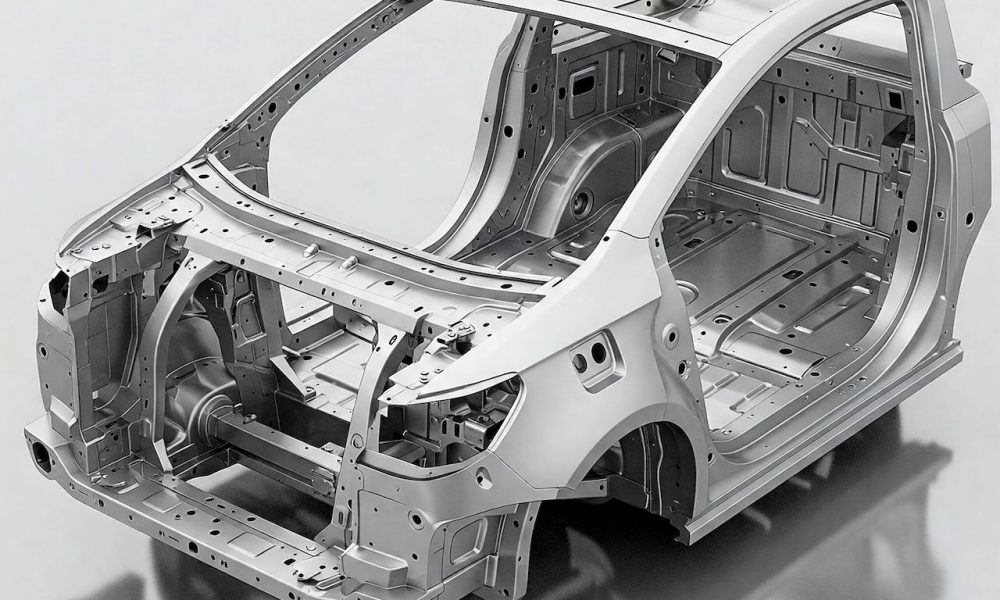

Aluminium Industry

Raw Materials: Bauxite is refined into alumina, which is then smelted into primary aluminium through electrolysis.

Key Processes:

- Casting: Produces aluminium ingots, plates, and profiles.

- Die Casting: Used for precision parts like automotive components and electronic housings.

- Extrusion: Manufactures construction profiles and industrial frames.

Applications: Aerospace, automotive, packaging (e.g., beverage cans), and construction (e.g., windows, curtain walls).

Trends: Lightweighting, increased use of recycled aluminium to reduce carbon emissions.

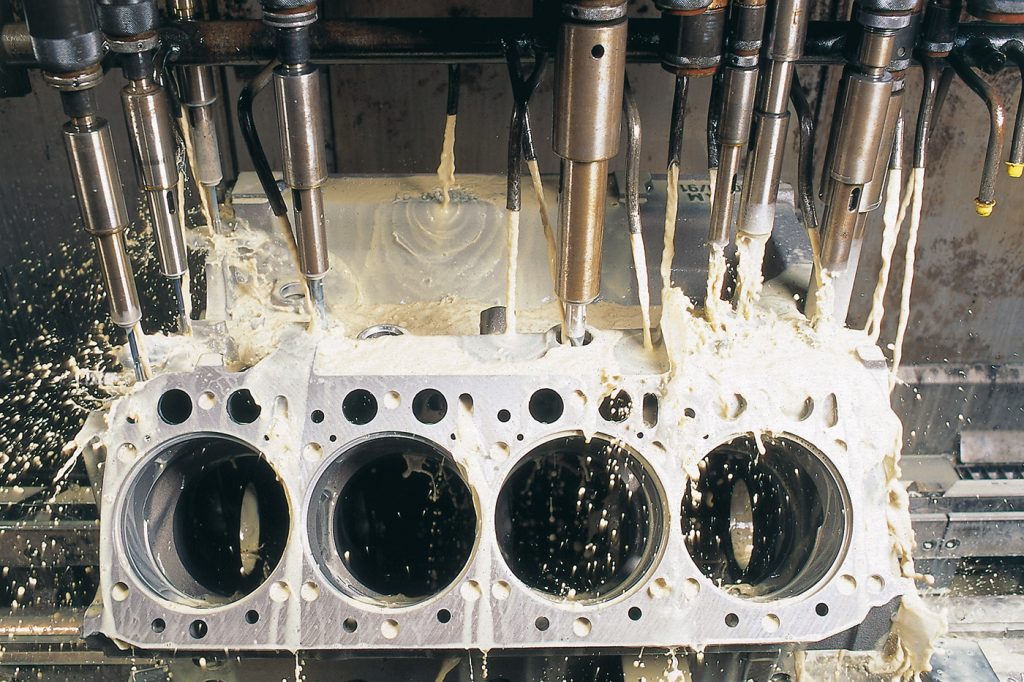

Cast Iron Industry

Raw Materials: Iron ore, scrap iron, and coke are smelted in blast furnaces to produce pig iron, which is further processed into cast iron.

Key Processes:

- Gray Iron: Good wear resistance, used in engine blocks and pipes.

- Ductile Iron: High strength, used in gears and crankshafts.

- Malleable Iron: High toughness, used in pipe fittings and construction fasteners.

Applications: Automotive, machinery, construction (e.g., manhole covers, pipes), and heavy equipment.

Trends: Development of high-strength cast iron, eco-friendly smelting (e.g., electric arc furnaces replacing blast furnaces).

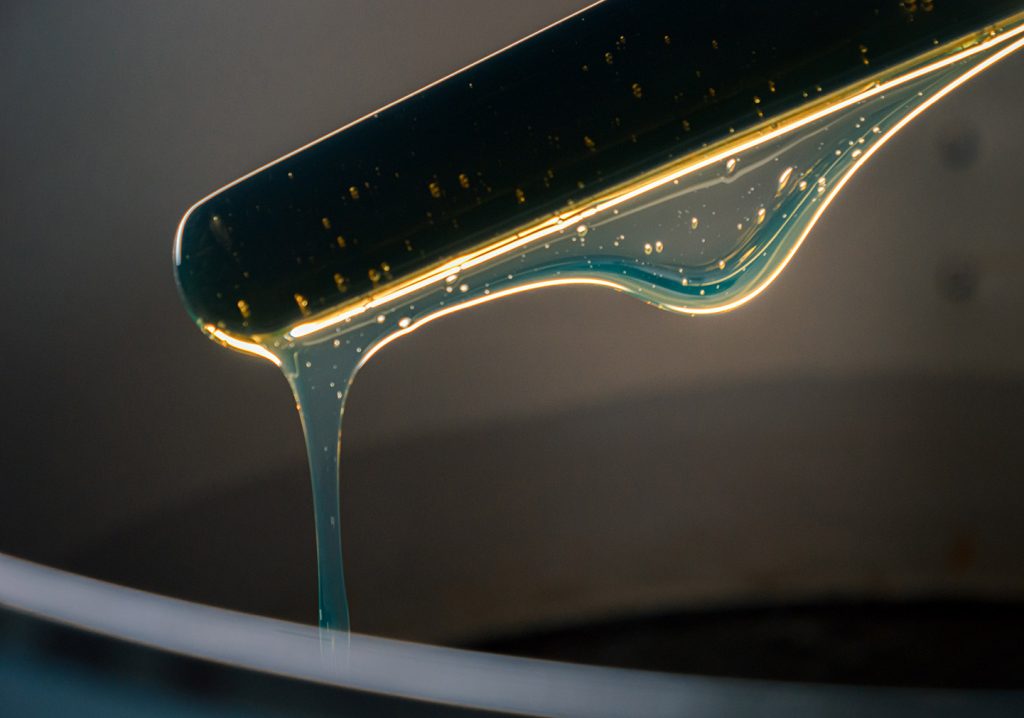

Specialty Lubricants in

Aluminium Cast Iron

Challenges in Casting & Die Casting:

- High Temperatures

Molten aluminium (around 660°C) and iron (1,200-1,500°C) require lubricants that can withstand extreme heat without breaking down. Regular oils burn away too quickly. - Sticking & Soldering

Molten metal tends to stick to molds and dies, causing surface defects. Special lubricants create protective barriers to prevent this fusion. - Wear & Corrosion

Abrasive materials in casting processes wear down equipment. Some lubricants can also cause corrosion if not properly formulated. - Release Performance

Good lubricants help separate finished parts from molds cleanly without damage or residue buildup. - Dimensional Accuracy

Proper lubrication ensures even cooling and prevents warping or porosity in final products.

Brugarolas Specialty Lubricant Solutions:

- For Casting (Sand/Gravity/Investment):

– Mold release agents using graphite or silicone bases

– Heat-resistant coatings for iron molds

– Water-based sprays with anti-weld additives for die casting - For Die Casting:

– Semi-synthetic fluids with extreme-pressure additives

– High-temperature greases for plunger systems

– Glass powder lubricants for very high temperatures - For Extrusion/Forging:

– Clean synthetic lubricants that don’t stain

– Special formulations that produce minimal smoke

Benefits:

– Tools last 30-50% longer

– Better surface quality on finished products

– Lower energy use due to reduced friction

– Safer, more environmentally friendly options available

Example: Proper lubrication can extend a die’s life from 50,000 shots to over 200,000 shots in aluminium die casting.

Brugarolas Industrial Solutions

| Application | Brugarolas Solutions | Performance |

|---|---|---|

| WATER-SOLUBLE RELEASE AGENTS | BESTRIL 1280 | Synthetic fluid, for aluminum, zamak and magnesium |

| WATER-SOLUBLE RELEASE AGENTS | BESTRIL 2040 | Synthetic fluid, for aluminum, zamak and magnesium |

| WATER-SOLUBLE RELEASE AGENTS | BESTRIL 2070 | Mineral oil for aluminum, zamak and magnesium |

| PURE RELEASE AGENTS | BESTRIL 2010 | Mineral oil, mid-high viscosity, for aluminum |

| PURE RELEASE AGENTS | BESTRIL 2050 | Pure oil. Flash point 70°C, for zamak |

| PLUNGER LUBRICANTS | BESTRIL FSP-320 | Mineral oil, mid viscosity |

| PLUNGER LUBRICANTS | BESTRIL FSP-EW | Internal container lubrication fluid |

| EJECTOR AND DISTRIBUTOR PASTES | BESLUX GRAFOL HT PASTE | Graphite lubricating paste |

| EJECTOR AND DISTRIBUTOR PASTES | BESLUX GRAFOL AL PASTE | Aluminum lubricating paste |

| Application | Brugarolas Solutions | Performance |

|---|---|---|

| GENERAL MAINTENANCE LUBRICANTS | FLUID DRIVE HLP range | DIN hydraulic oil, HLP, ISO VG 32, 46, 68 |

| GENERAL MAINTENANCE LUBRICANTS | HIDROSECUR A-1100 | Fire-resistant hydraulic oil ISO HFC, ISO VG-46 |

| GENERAL MAINTENANCE LUBRICANTS | BESTERM HT | Thermal oil |

| GENERAL MAINTENANCE LUBRICANTS | BESTRIL 570 | Cutting press oil |

| ALUMINUM MACHINING FLUIDS | SERVOL 2511 | Water-soluble fluid for aluminum machining |

| ALUMINUM MACHINING FLUIDS | SERVOL 5550 | Water-soluble fluid for aluminum machining |