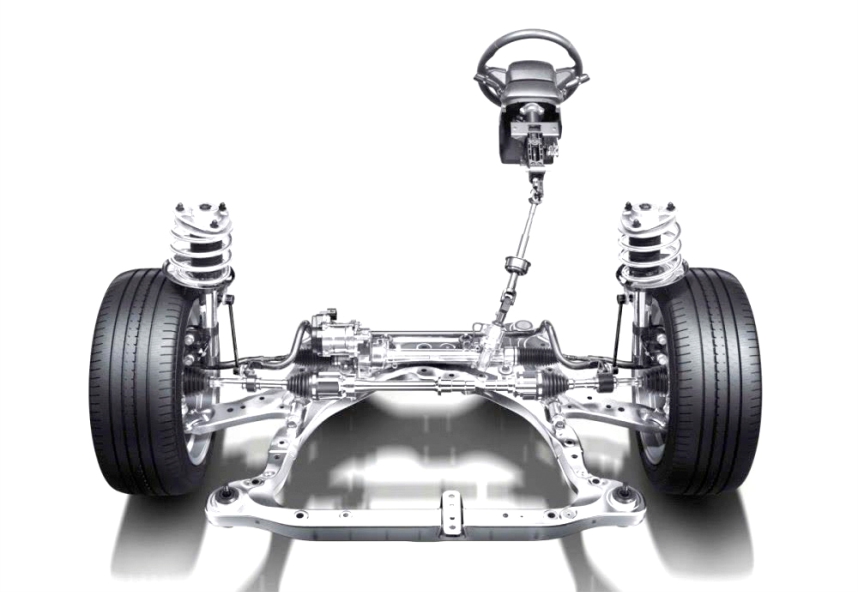

Steering System Lubricants

The lubrication requirements for steering systems include low-temperature torque, rust and corrosion prevention, excellent wetting properties, and resistance to fretting corrosion. For high-end vehicle models, attention is also given to NVH (Noise, Vibration, and Harshness) issues, such as noise reduction.

Our Strength:

1. Low-Temperature Torque

2. Rust and Corrosion Prevention

3. Excellent Wetting Properties

4. Resistance to Fretting Corrosion

5. Noise Reduction (NVH Performance)

6. Long-Lasting Lubrication

7. Material Compatibility (e.g., with seals and elastomers)

8. Smooth and Precise Operation

9. High Load-Bearing Capacity

10. Temperature Stability

11. Water and Contaminant Resistance

12. Wear Protection

13. Low Friction for Energy Efficiency

14. Vibration Damping

15. Compatibility with Electric Power Steering (EPS) Systems

Steering System Lubricants

| Lubrication Point | Brugarolas Solutions | Characteristics/Compliance Standards |

|---|---|---|

| Electronic Steering Device | G.BESLUX PLEX 778B TF PLUS | FICOSA |

| Steering Column | G.BESLUX TRIBOPASTE L-32 S | Resistant to high and low temperatures, noise reduction |

| Electronic Steering Device | G.BESLUX PLEX DPH 8113 G.BESLUX LIPLEX L-1/2 STF G.BESLUX XP-151 | ZF-TRW |

| Hydraulic Steering System | G.A. N.80/M-482 | TRW AUTOMOTIVE TMS-L-10482 |

| Steering System | G.A. N.85/1 TRW | TRW AUTOMOTIVE TRW-31 815 252 |

| Rack and Pinion | G.A. N.80/M-481 PLUS | Wear-resistant, extreme pressure-resistant, strong adhesion |

| Worm Gear | G.BESLUX PASTE 778A/1 G.BESLUX PLEX DPH 8113 | Low-temperature startup, extrusion-resistant, wear-resistant |

| Ball Screw | BESLUX GEAR ET 220 | Extrusion-resistant, strong adhesion, water-resistant |

| Bellows | G.A. BESSIL 25 | Good rubber compatibility, resistant to high and low temperatures |

Automotive chassis actuators receive signals from the ECU to execute specific mechanical actions. To address lubrication requirements in next-generation chassis actuators like steer-by-wire and brake-by-wire systems, Brugarolas has developed a comprehensive product line based on various base oils to meet diverse OEM needs.

Our solutions include:

– Specialty greases for electric steering actuators

– Advanced lubricants for electric brake actuators

Each formulation features tailored chemical compositions and viscosity grades optimized for:

✓ Different actuator architectures

✓ Enhanced wear resistance

✓ Improved low-temperature efficiency

For EVs (Electric Vehicles) and future trends, steering systems will focus more on the following aspects:

– Electric Power Steering (EPS)

– Advanced Driver-Assistance Systems (ADAS)

– Autonomous Driving

– NVH (Noise, Vibration, Harshness)

– Thermal Stability

– Energy Efficiency

– Lightweight Materials

– Sustainability

– Friction Reduction

– Precision Steering