Case Study Open gear

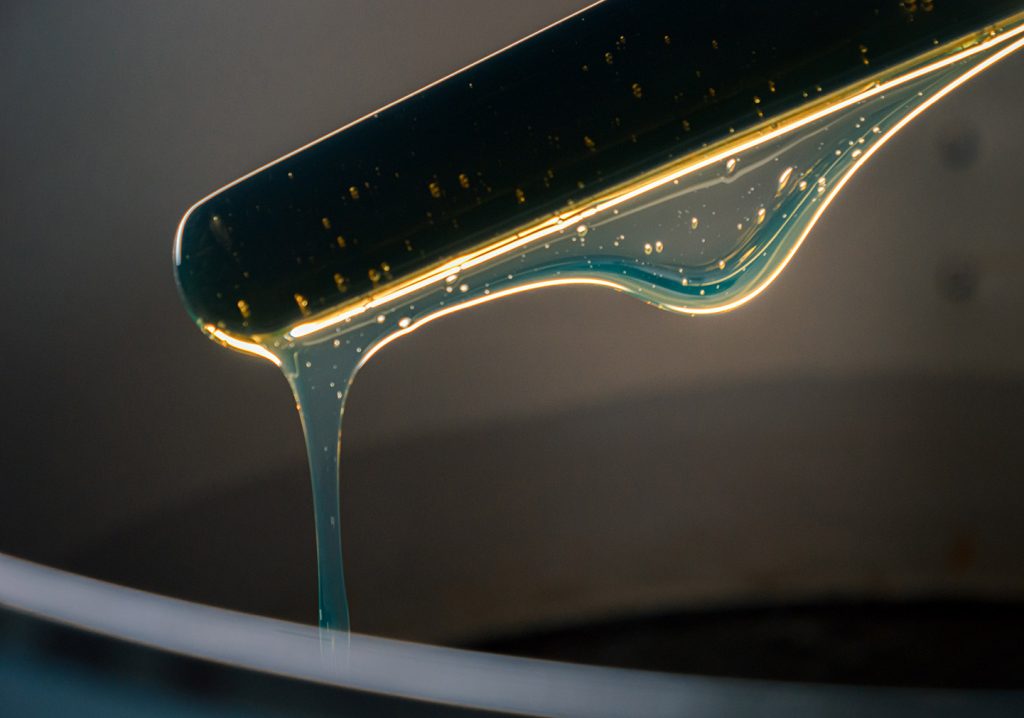

Open gears operate for extended hours under extreme loads, high temperatures, and dusty environments—conditions that make ongoing wear a critical challenge. Left unchecked, this wear can cause unplanned downtime, shorten equipment lifespan, and drive costly replacements.

To address these risks, leading mining, cement, paper, chemicals companies rely on advanced grease technologies combined with technical inspections. This approach helps prevent gear failure, extend service life, and maintain reliable, efficient operations.

Two main systems: oil bath and spray system

For open gear lubrication, two primary systems are commonly applied in practice: the oil bath system and the spray system. The oil bath method relies on partially immersing the gears in a lubricant reservoir, providing continuous coverage with a relatively simple setup, though it may result in the contamination and heat build-up. In contrast, the spray system delivers lubricant directly onto the gear surfaces in a controlled manner, ensuring precise distribution, better cooling, and improved efficiency under demanding conditions, albeit with higher complexity, maintenance requirements and initial cost. Choosing between the two depends on operating conditions, gear size, and the balance between cost efficiency and performance reliability.

Oil bath system

An oil bath system is one of the simplest methods of open gear lubrication, where the gear set is partially submerged in a reservoir of lubricant. As the gears rotate, the lubricant is carried up and distributed across the tooth surfaces, ensuring continuous coverage and reducing metal-to-metal contact. This approach offers the advantages of straightforward design, relatively low installation cost, and minimal monitoring requirements.

Oil bath systems are most commonly found in smaller mills, gearboxes, small grinding mills, mixers, dryers, or rotary kilns , older equipment designs.

Advantages:

- Simple design and lower initial cost

- Continuous lubrication coverage

- Less complex control/monitoring requirements

Oil bath limitation

- Contamination risks

- Heat build-up and oxidation risks

- Not suitable for very large or high-speed gears

Due to challenging site conditions and varying equipment states, an oil bath operating over long periods without sufficient monitoring can easily become contaminated. This contamination may repeatedly damage open gears, reduce operational efficiency, and deteriorate tooth surface conditions. As modern large gears face increasing transmission demands under heavy loads, the oil bath system often fails to provide adequate protection. For this reason, more and more equipment which more precise lubrication and cooling are needed has shifted toward the use of spray lubrication systems.

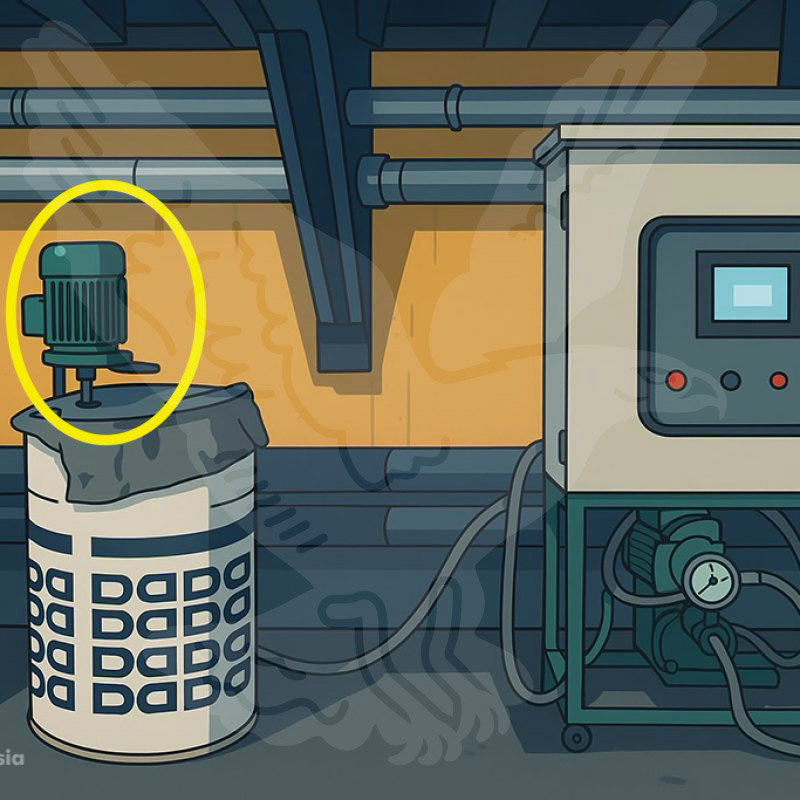

Spraying system

A spray lubrication system applies lubricant directly onto open gear tooth surfaces through nozzles that deliver a fine, targeted spray or mist. This method ensures precise coverage and optimal film formation, reducing lubricant waste while providing better cooling and minimizing the risk of oxidation and contamination compared to oil bath systems. Spray systems are especially effective for large, high-speed, or heavily loaded gears where continuous and controlled lubrication is critical for performance and reliability.

Spraying limitation

- Nozzle blockage

- Insufficient or unbalance spray volume

- Impact of dusty or humid environments

- System pressure or flow abnormalities

- On-site monitoring is needed

The system requires pumps, nozzles, and controls to operate consistently, which increases installation and maintenance costs, and its effectiveness can be compromised if the nozzles become clogged or misaligned.

To resolve the old-type spraying system shortage, Brugarolas offers a brand new BESLUXLUBE spray system with its BESLUX open gear range lubricants to benefit your equipment.

Why choose BESLUX?

Brugarolas S.A.

Founded in 1885 and headquartered in Barcelona, Spain, Brugarolas Lubricants is dedicated to innovation in lubricant applications. All products comply with the RoHS directive, ensuring import and export without concerns over restricted substance testing. Our solutions extend equipment lifetime and reduce operating costs. With a full product line covering a wide range of industries—including cement, mining, food, paper, aerospace, and advanced electronics—if you require specialized lubrication products not listed below, contact our engineers with hesitation.

Our Advantages:

- Reduce friction and wear, minimize abnormal noise

- Extend component lifetime

- Prevent contamination

- Enhance functionality and reliability

- Improve production yield

- Avoid product defects

- Increase uptime

- Low odor

- Safe for operators

- Non-hazardous

- Lower overall costs

- RoHS and REACH/SVHC compliant

- PFAS free

- MOSH/MOAH free

- Biodegradable