What is NSF?

The National Sanitation Foundation (NSF), founded in 1944 in the US, is an organization dedicated to public health and environmental protection.

When it comes to food-grade lubricants, NSF classifies them into the following categories:

- NSF H1

- NSF H2

- NSF H3

- NSF 3H

Among these, NSF H1 lubricants are designed for situations where incidental or indirect contact with food or beverages may occur. They can be used as protective anti-rust films on food processing equipment, as release agents for gaskets or seals, or as lubricants for machine parts and equipment that may come into contact with food. For the general maintenance such as the gearbox, chain, bearing, compressor, hydraulic system in food factories, it is recommended to apply NSF H1 lubricants.

NSF Food-Grade Lubricant Categories & Definitions

| NSF Category | Definition |

|---|---|

| NSF H1 | For use in situations where incidental or indirect contact with food may occur. Typical applications include protective anti-rust films on food-processing equipment, release agents for gaskets or seals, and lubricants for machine parts such as bearings, chains, or slides that may come into contact with food. Formulations must comply with relevant positive lists (e.g., FDA 21 CFR) and be registered with NSF. |

| NSF H2 | Intended for equipment and areas where there is no possibility of food contact. Not permitted for any part that may touch food. Compared to H1, H2 products face fewer formulation restrictions, but still need to meet safety and regulatory requirements. |

| NSF H3 | Edible oils used as direct contact rust preventatives. Commonly applied to meat hooks, trolleys, knives, cutting boards, or similar equipment. Surfaces treated with H3 lubricants may come into direct contact with food. |

| NSF 3H | Used as direct contact release agents on surfaces such as baking pans, molds, cooking vessels, or cutting equipment to prevent sticking and aid release. Some products may carry dual registration (3H/H1), providing broader application flexibility. |

What is NSF 3H?

NSF 3H lubricants are specially approved for direct contact with food. They are mainly used as release agents to prevent food from sticking to surfaces such as baking pans, molds, cutting boards, or cooking vessels. This makes them different from NSF H1 lubricants, which are only for incidental contact. With 3H certification, the lubricant is safe to touch food directly, ensuring both smooth production and consumer safety.

Frequently asked

Why should I use lubricants with NSF H1 certification?

Based on different exposure risks, equipment such as baking ovens, conveyors, and mixers are required to use NSF H1 certified lubricants to reduce the risk of secondary contamination. Typical examples include food-grade gear oils, food-grade compressor oils, and food-grade bearing greases.

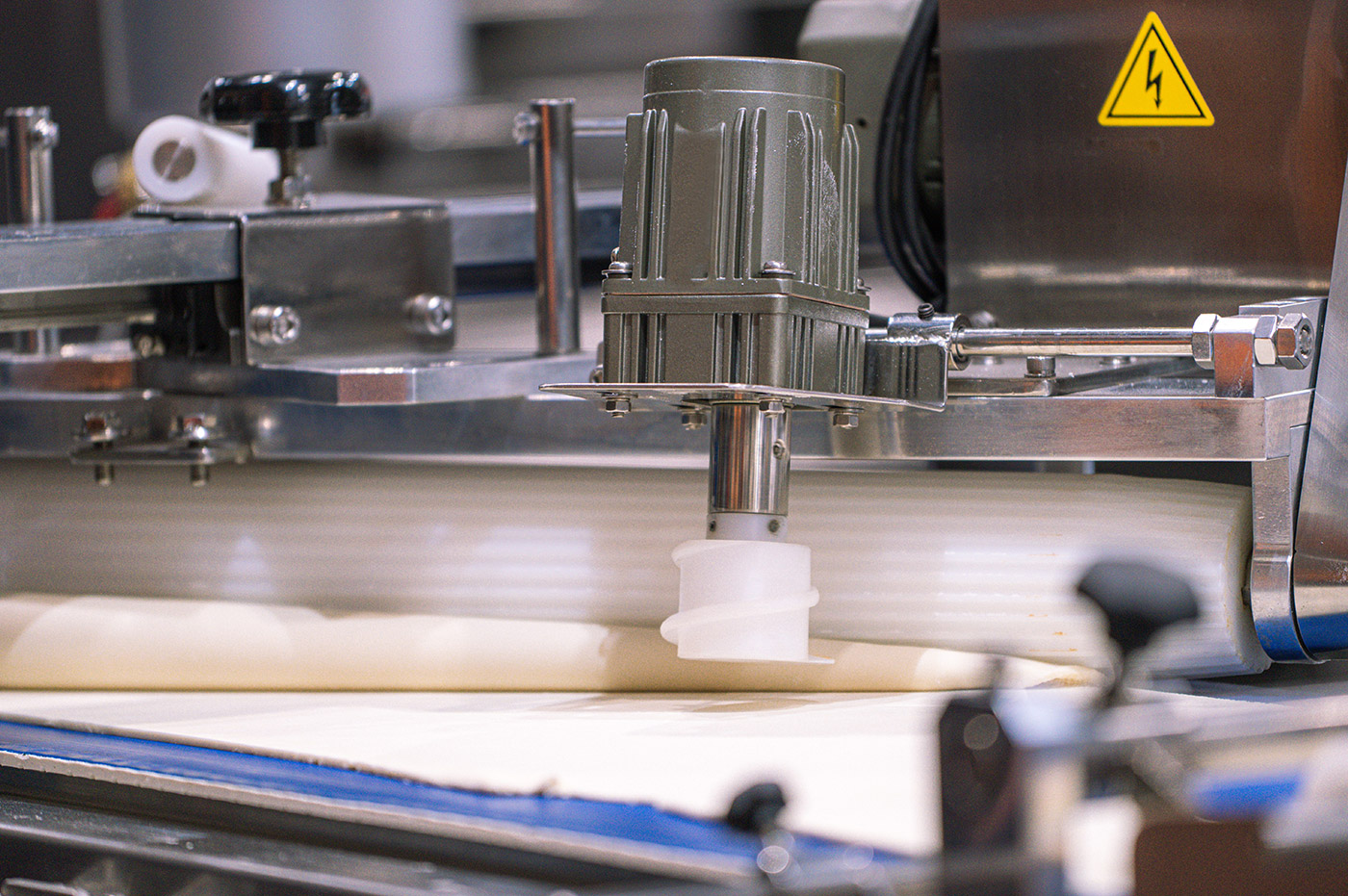

Why should I use release agents (pan oils) with NSF 3H certification?

In applications like dough dividers, plant oils or white mineral oils are often used as release agents (pan oils). Because these substances come into direct contact with the dough, they are required to be NSF 3H certified to reduce risks of contamination and ensure food safety.

Can I use regular cooking oil from the supermarket instead of NSF 3H certified pan oil?

It depends. For large-scale industrial production, using cooking oil is not recommended. In mass production, consistency and safety are critical. Cooking oils are more prone to bacterial growth, oxidation, and off-odors, which increase the burden on staff and compromise product quality. Certified NSF 3H pan oils, on the other hand, resist blackening of pans, withstand higher temperatures, and provide longer service life. For these reasons, many leading brands already choose NSF 3H certified pan oils.

Isn't NSF 3H and H3 the same?

Although NSF 3H and NSF H3 sound similar, they are in fact two different categories. NSF 3H refers to food release agents that can be directly applied to food contact surfaces such as baking pans or molds to prevent sticking, while NSF H3 refers to soluble edible oils commonly used on food processing equipment surfaces such as knives or hooks, mainly to prevent rust and to keep food from drying or sticking.

Beyond lubricants—what else should be considered?

Cleaning agents used in food and pharmaceutical plants should also comply with food-grade standards. These are classified as NSF A1 certified cleaners. Always request supporting documentation from your supplier. Note: if your supplier only provides an NSF H2 certificate, it is not valid for food-contact production lines.

NSF H1, NSF 3H, when?

When to Use NSF H1 Food-Grade Lubricants

- For situations where there may be occasional contact with food

- For areas with indirect contact with food

- Must be tasteless, odorless, and non-toxic

- Suitable for lubrication points that face high temperature, high speed, or exposure to moisture and steam

- Commonly applied in food machinery such as bearings, slides, gearboxes, and air compressors

When to Use NSF 3H Food-Grade Lubricants

- For applications where direct contact with food occurs

- Must be tasteless, odorless, and non-toxic

- Commonly used as release agents, such as pan oils or demolding oils

Brugarolas S.A.

Founded in 1885 and headquartered in Barcelona, Spain, Brugarolas Lubricants is dedicated to innovation in lubricant applications. All products comply with the RoHS directive, ensuring import and export without concerns over restricted substance testing. Our solutions extend equipment lifetime and reduce operating costs. With a full product line covering a wide range of industries—including cement, mining, food, paper, aerospace, and advanced electronics—if you require specialized lubrication products not listed below, contact our engineers with hesitation.

Our Advantages:

- Reduce friction and wear, minimize abnormal noise

- Extend component lifetime

- Prevent contamination

- Enhance functionality and reliability

- Improve production yield

- Avoid product defects

- Increase uptime

- Low odor

- Safe for operators

- Non-hazardous

- Lower overall costs

- RoHS and REACH/SVHC compliant

- PFAS free

- MOSH/MOAH free

- Biodegradable

- Food-grade

- Halal certification