Textile industry

Specialty Lubricants in

Textile Industry

In a textile factory, various machines require specialty lubricants to ensure smooth operation, reduce wear, and prevent contamination. Here are the key machines that benefit from specialty lubricants:

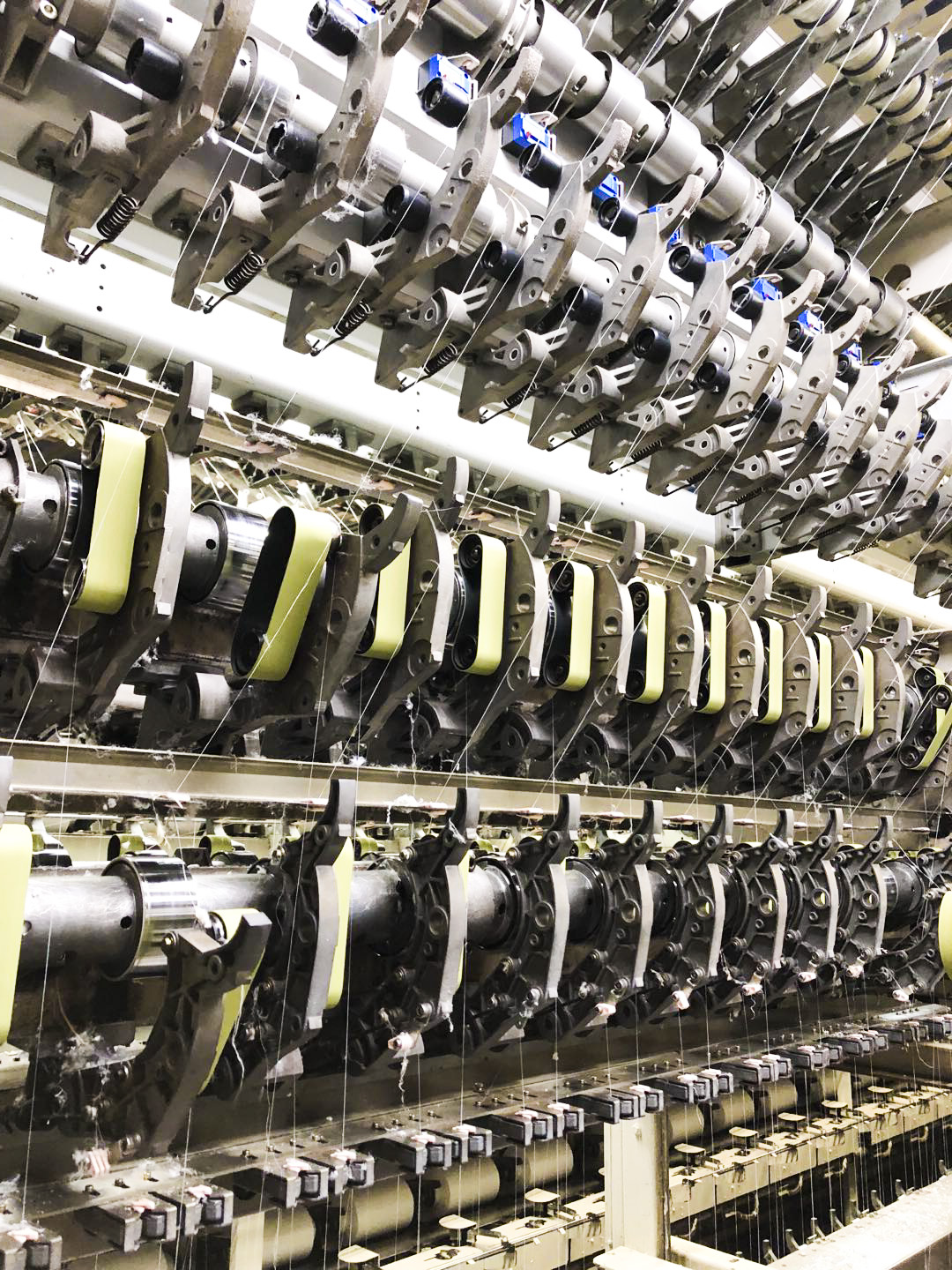

1. Spinning Machines • Ring Spinning Frames • Open-End (Rotor) Spinning Machines • Carding Machines

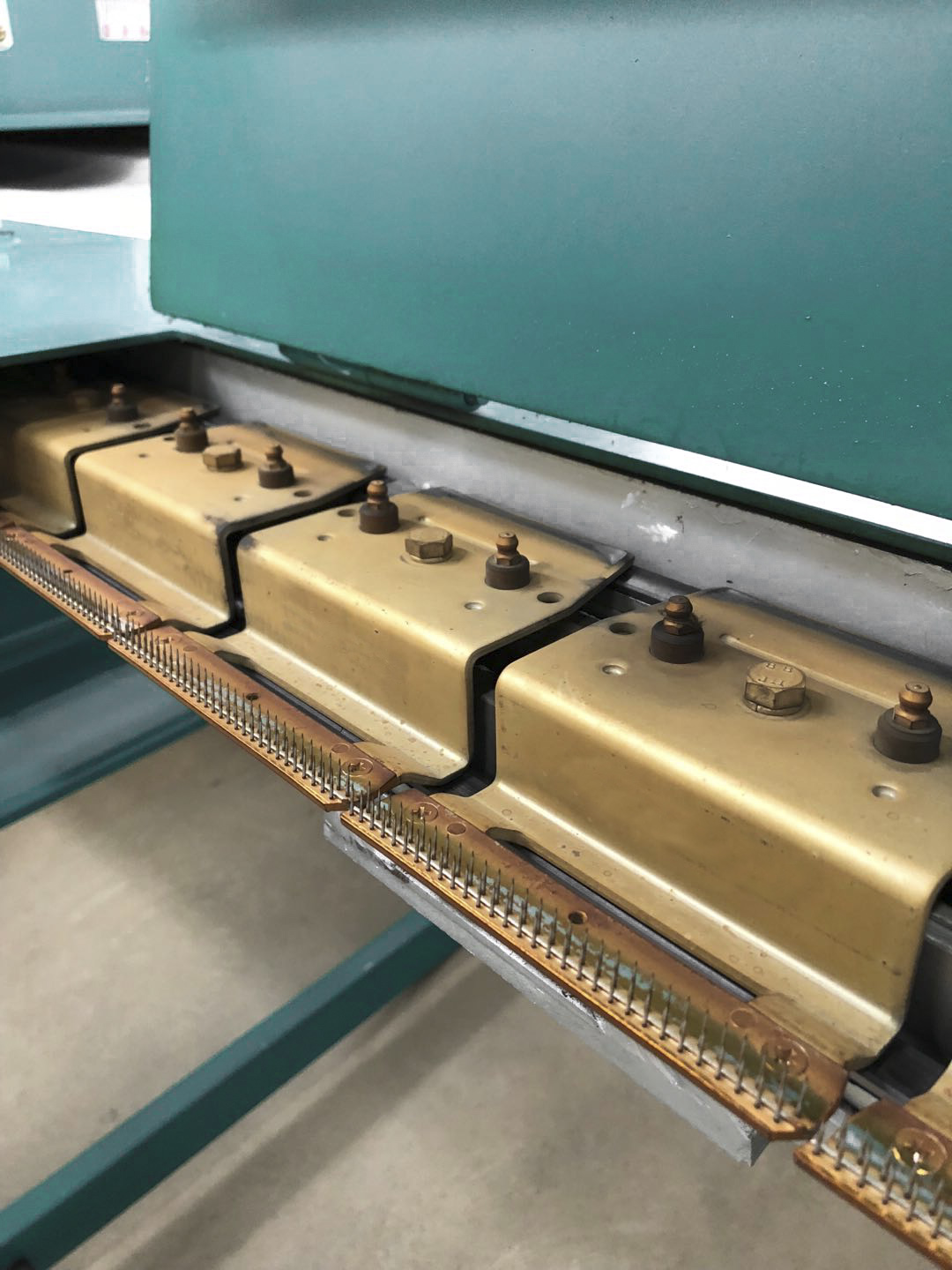

2. Weaving Machines • Looms (Rapier, Air-Jet, Water-Jet, Projectile, Shuttle Looms) • Warping and Sizing Machines

3. Knitting Machines • Circular Knitting Machines • Flat Knitting Machines

4. Dyeing and Finishing Machines • Dyeing Machines • Stenter Machines • Calendaring Machines

5. Nonwoven Fabric Machines • Needle Punching and Spunbond Machines

6. Sewing and Embroidery Machines • Industrial Sewing Machines • Embroidery Machines

7. Conveyor and Material Handling Equipment • Conveyor Belts and Rollers • Pneumatic and Hydraulic Systems

Brugarolas Solutions

Spinning machine and knitting machine lubricating oil

Suitable for use in roving machines, spinning machines, twisting machines, ring spinning machines, etc. In these machines, due to very high speeds, there is a need for anti-wear oils, washable oils, and high-resistance lubricating greases. They provide and prolong re-lubrication, minimize oil consumption, and ensure stable operation without wear.

Recommended for use in sock machines, warp knitting machines, circular machines, and raschel machines. Generally used in all knitting machines and places requiring synthetic and mineral oils. Easy to disassemble, good wear resistance, excellent penetrability, suitable for needle lubrication, and common operation in this field across all machines.

| Lubrication point | Brugarolas solutions | Features |

|---|---|---|

| Large circular knitting machine | BB TEX 22 | Synthetic knitting oil with excellent emulsification, anti-wear, anti-oxidation, anti-static properties, and resistance to oil mist. Ensures reduced wear of moving parts during startup and prolonged operation, providing effective lubrication. |

| Rotating plates (sliding bearings) in the carding machine and combing machine. | G. BESLUX WHITE LUBRICANT PASTE | Used for dry lubrication, this white lubricating paste is non-staining and exhibits excellent anti-seize and lubrication properties. It forms a durable anti-friction lubricating film. |

| Top and bottom roller bearings of the combing machine | G. BESLUX PLEXBAR range | Used for high and medium-speed applications, this low viscosity lubricating grease offers resistance against acids, alkalis, and steam. It ensures long-lasting performance. |

| Bearings of the drafting system in the fine yarn spinning machine | G. BESLUX PLEXBAR M-2 | Low viscosity barium complex lubricating grease. Especially suitable for ultra-high-speed bearings. Outstanding water resistance, weak acid, or weak alkali resistance. |

| Open-end roller (spinning machine) | G. BESLUX PLEX BAR L-2/S | Low viscosity barium complex lubricating grease. Especially suitable for ultra-high-speed bearings. Outstanding water resistance, weak acid, or weak alkali resistance. |

| Open-rotor turbine (dual-disc drive) | G. BESLUX PLEX L-2/S | Low viscosity lubricating grease for ultra-high-speed bearings. Fully synthetic oil for high-speed. |

| Electric motor | G. BESLUX KOMPLEX ALFA II | Long-life polyurea lubricating grease. Blue color. Long-lasting lubrication. |

| Main spindle box, gearbox | G. BESLUX KOMPLEX L-2 AZUL | High-speed gear oil designed for excellent heat performance and high wear resistance. Resistant to micro-pitting. |

| Chain and open gear transmission | BESLUX CAMIN 4200 | High adhesion, wear-resistant, oil-repellent, non-dripping, and non-splashing. |

| Hydraulic transmission | BESLUX FLUID DRIVE HM | High-performance hydraulic oil. Oxidation stability and corrosion resistance. |

Lubricating oil for weaving processes.

For rapier looms, shuttleless looms, air jet looms, projectile looms, warping machines, and twisting machines, high loads and centralized lubricating oil, as well as long-life lubricating grease, are needed. This can reduce maintenance costs and extend equipment lifespan.

| Lubrication point | Brugarolas solutions | Features |

|---|---|---|

| Shuttleless weaving machine | G. BESLUX PLEXBAR M-2 | Barium complex grease. Offers excellent resistance to water, steam, and even weak acids or bases. |

| Central weaving machine guide rail oil | BESLUX LUDER range | Anti-stick, wear-resistant, and metal-adhesive performance oil. Suitable for centralized lubrication system pipelines, non-clogging. Complies with Cincinnati P-50 specification. |

| Electric motor coupling with brake and slider, sword bar guide roller, distributor | G. BESLUX PLEXBAR L-2/S | Low viscosity barium complex grease. Particularly suitable for ultra-high-speed bearings. Outstanding water resistance and resistance to weak acids or weak alkalis. |

| Weaving machine gears | BESLUX GEARSYNT range | Fully synthetic gear oil. Designed to ensure gears are protected from wear and corrosion. High viscosity index, with viscosity that remains stable with temperature changes. |

| Open gear lubrication | G. BESLUX GFG | Open gear lubricant. Used for bevel gear lubrication. It provides effective lubrication up to 150 degrees Celsius and dry lubrication up to 450 degrees Celsius. Forms a highly adhesive oil film to protect gear surfaces from wear and micropitting. |

| Chain lubrication | BESLUX CAMIN 4200 | High-adhesive chain oil. Excellent anti-wear and lubrication properties. Its high viscosity prevents dripping and splashing. Recommended for temperatures up to 150 degrees Celsius. |

Lubricating oils and greases for setting machines and dyeing processes.

Suitable for draw texturing machines, layer draw machines, dyeing tanks, printing machines, calenders, beater machines, dyeing machines, and more. Chains operating at temperatures exceeding 230°C require specialized high-temperature synthetic chain oils to prevent wear. Additionally, there are lubricating greases resistant to water, steam, acidic and alkaline solutions, and high temperatures. These products offer extended service life, prolonged maintenance intervals, and reduced maintenance costs.

| Lubrication point | Brugarolas solutions | Features |

|---|---|---|

| High-temperature transfer chains for horizontal or vertical setting machines | BESLUX RAMCA 220 / 320 | Used for high-temperature chains and sliding guides, this fully synthetic chain oil does not form sludge at temperatures exceeding 230°C. It performs exceptionally well on the frame of a stretching machine. |

| High-temperature setting machine bearing chains and chains supported by ball bearings | G. BESLUX FLUOR H-2, G. BESLUX FLUOR FG 222 | High-viscosity PTFE fluorinated grease. Capable of operating at temperatures up to 280°C. Non-flammable. Highly resistant to acids. Highly compatible with plastics and elastomers. Non-toxic, food-grade (NSF H1). Extremely slow aging. Long-lasting lubrication. Significantly reduces lubrication frequency. Extremely low friction coefficient. Suitable for high-temperature bearings in German and Taiwan setting machines. |

| Fan and exhaust fan bearings lubrication | G. BESLUX KOMPLEX ALFA II, G. BESLUX KOMPLEX 412 SW, G. BESLUX KOMPLEX HT-2/S | Suitable for high-temperature long-life synthetic lubricating grease. It can provide effective lubrication even at temperatures reaching up to 180°C or even 200°C peak temperatures. |

| Rolling bearings in washing machines, silk machines, dyeing machines, and trolleys | G. BESLUX PLEXBAR M-2 | Barium complex lubricating grease. It exhibits excellent resistance to water, steam, and even weak acids or bases. |

| Vertical dryer high-temperature bearings, pulper bearings | G.BESLUX SULPLEX FG 462/S | Full synthetic high-temperature grease, resistant to acid and alkali, suitable for high-temperature environments, and has a long service life. |

| High-temperature lead screw | BB 202 | Molybdenum disulfide coating, suitable for protection and dry lubrication at temperatures up to 450°C. |

| Chain lubrication | BESLUX CAMIN 460 WR | Water-resistant high-adhesion chain oil. Can be used manually or with an automatic oiling system. Excellent anti-wear and lubrication performance. Operating temperature up to 150°C. |

| Pneumatic devices lubrication | BESLUX NEULUB 22 | Specialized oil for protecting air pipelines and valves from corrosion and oxidation. |

DESENGRAS ECO 7075, eco-friendly cleaning agents for textiles industry.

Product Overview

Citrus Lemon Scent Fully compliant with the new China standard: VOC “GB38508-2020 Cleaning Agent Volatile Organic Compounds” specification. Friendly to aluminum, copper, iron, and their alloys, non-corrosive to car components, leather, and other materials for cleaning. It is a biodegradable, water-based cleaning agent.

Usage Instructions

Used for cleaning black metals (steel, cast iron, etc.) and aluminum alloys (including aero aluminum 7075). It can also effectively remove oil stains from non-ferrous metals without leaving residues. This product is highly suitable for cleaning wastewater pits (e.g., on CNC machines), floors, walls, moving equipment, tools, elevators, heavy machinery, etc. It can also be used in ultrasonic cleaning machines.

Instructions for Use and Applications (Dilution with Water)

| Illustration | Heavy | Conventional | Slightly | High pressure machine |

|---|---|---|---|---|

| Proportion | 1:4 | 1:4 to 1:10 | 1:3 to 1:10 | 1:20 |

| Usage | Grease/oil plant equipment, oil transfer tools, heavily soiled engines, compressors, application machinery, extremely dirty workshop areas, coal and locomotive cleaning. | Trucks/trailers, machinery equipment, workshop floors, workshop walls, parts preparation, and application equipment cleaning. | Routine operations involve cleaning of surfaces, equipment, and preparation areas. | Appliances, toilets, sinks, floors, general vehicle washing, bathroom and soap scum cleaning. Window, windshield, and mirror cleaning. |