Paper industry

Specialty Lubricants in

Paper/Pulp/Corrugated Industry

Paper production is a complex process with numerous critical lubrication points exposed to challenging environments, including high temperatures, presence of water, water vapor, loads, speeds, and more. The performance of production plants directly relies on the effective lubrication of their systems. Lubrication failures or improper lubrication can result in issues ranging from disrupted paper production, low yield, and decreased operational KPIs to potentially shutting down the production line or severe machinery damage before scheduled maintenance.

From pulp, recycled paper, to corrugated paper, Brugarolas offer a comprehensive range of solutions tailored for your specialized industry needs.

Open gears play a crucial role in pulp production by driving and transmitting power to large industrial machinery used in various stages of the process.

- Driving Rotary Equipment: rotary kilns, digesters, and dryers,

- Powering Pulping Machines: agitators, refiners, and mixers

- Operating Conveyors and Rollers: conveyor belts, rollers, and drum washers

- Supporting Paper Machine Components : press sections and large rollers

Due to the high loads, moisture, and contaminants in pulp mills, proper lubrication and maintenance of open gears are critical for efficiency, longevity, and minimizing downtime.

Brugarolas Solutions

| lubricant | Thickener | temp. | capability |

|---|---|---|---|

| G. BESLUX SULPLEX H- 1/2 PLUS | Calcium sulfonate | -15 to 160[Peak 180] | Lubrication for bearings, rollers, dryers, and guides exposed to high loads, water, steam, and high temperatures. |

| G. BESLUX SULPLEX M- 2 PLUS | Calcium sulfonate | -20 to 160[Peak 180] | |

| G. BESLUX PLEX BAR H-2 | Barium | -15 to 150 | Lubrication of Bearings Exposed to Extreme Temperatures |

| G. BESLUX PLEX BAR M-2 | Barium | -15 to 150 | |

| G. BESLUX FLUOR H-2(NSF H1) | PTFE | -30 to 260 | Roller bearings require prolonged lubrication protection in extremely high-temperature environments and comply with NSF H1 food-grade certification. |

| G. BESLUX KOMPLEX HT-2/S | Polyurea compound | -20 to 200 | Lubrication for roller bearings in high-temperature environments. |

| G. BESLUX KOMPLEX 412 SW | Polyurea compound | -20 to 200 | Long-lasting lubrication for roller bearings in high-temperature environments. |

| G. BESLUX KOMPLEX ALFA II | Polyurea compound | -50 to 180 | Long life lubricating for electric motor bearings. |

| G. BESLUX GFG | Inorganic | -10 to 150[Peak 450] | Open gear grease for heavy load |

| G. BESLUX CROWN EH-2 WM | Aluminum | -30 to 150[Peak 450] | White grease for open gear |

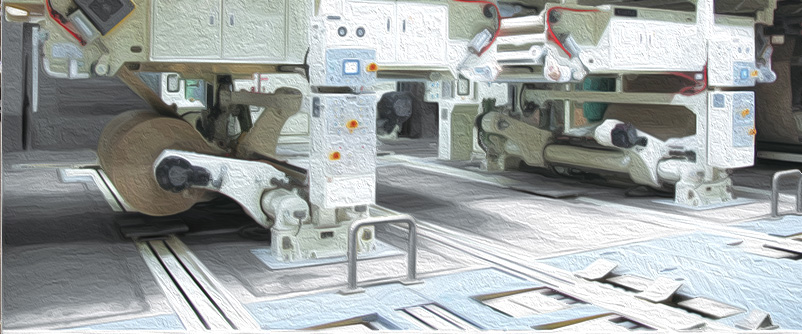

- In the competitive global market, corrugated board manufacturers must ensure the utmost performance of their machinery. This translates to equipment requiring longer lifespans, reduced maintenance and downtime, all while producing high-quality end products.

- Enhancing bearing reliability and efficiency of corrugation machinery rests on two primary criteria: wear resistance and friction reduction. Our high-quality products are formulated specifically for bearings on single facer machine heating rolls, ensuring their continuous operation under extreme temperatures and loads.

Typical Application

Usage | No. | Lubricants | Features | Package |

| Corrugated roll bearings | 1 | G.BESLUX FLUOR H-2 | PTFE grease, excellent to high temperature for long-term usage. | 800g 1KG |

Preheating wheel bearing | 2 | G.BESLUX KOMPLEX 412 SW | Synthetic polyurea Long life high temperature synthetic grease. | 400g 18KG |

Preheating wheel bearing | 3 | G.BESLUX KOMPLEX HT-2/S | Synthetic polyurea grease. Long life usage. | 400g |

Heavy load low speed & high-pressure bearings | 4 | G.BESLUX SULPLEX H-2 PLUS | Highly efficient and long-lasting, suitable for applications involving resistance to seawater and heavy loads. | 400g 15KG |

Conventional lubrication | 5 | G.A. PLEX 2 | Multi-purpose lubrication grease | 400g 15KG |

High temp. dry lubrication | 6 | BESLUX MOLY SPRAY | High temp. dry lubrication spray aerosol Peak up to 450°C | 400ML |

| Lubrication and rust prevention | 7 | BASIC MULTIUSO SPRAY | Prevents rust, provides lubrication, and safeguards against moisture-induced loosening for screws and components. | 400ML |

Chain/Slide lubrication | 8 | BESLUX CAMIN 150 WR SPRAY | Long life lubrication for chain and slide | 400ML |

| Open gear lubrication | 9 | G.BESLUX CROWN M FLUID | Fluid grease. Excellent protection to the gear surface. | 50L, 185KG |

High-temperature anti-seize for screws. | 10 | ANTI-SEIZE PASTE 1 ANTI-SEIZE 2 | Easy to install and disassemble, anti-seize paste include solid additive | 1KG |

The aforementioned products* features include:

- Significantly reduced wear at friction points.

- Decreased friction coefficient.

- No oxidation or adhesive residue formation.

- Enhanced operational stability under roller pressure.

- Lower volatility at high temperatures to minimize oil evaporation.

- Minimal base oil leakage, ensuring lubricant stability.

*Paper mill equipment includes many portfolio. If you have equipment that is unclear or not mentioned above, feel free to contact us. With over 40 years of experience in the paper industry, Brugarolas has conducted lubrication fundamental training with major manufacturers and equipment exporters. Our technical experts are available for consultation at any time.