Electronics industry

Specialty Lubricants in

ELECTRONICS INDUSTRY

The lubricants used in the electronics industry are vital and special, including lubricating oils and greases. Different lubricants are required for various environments such as cleanrooms and production line machinery. It is also possible to incorporate automatic lubrication systems as part of the overall factory planning.

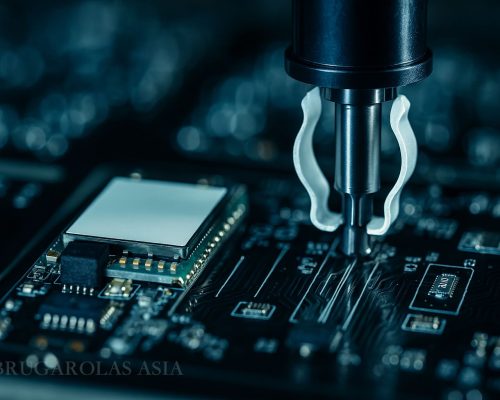

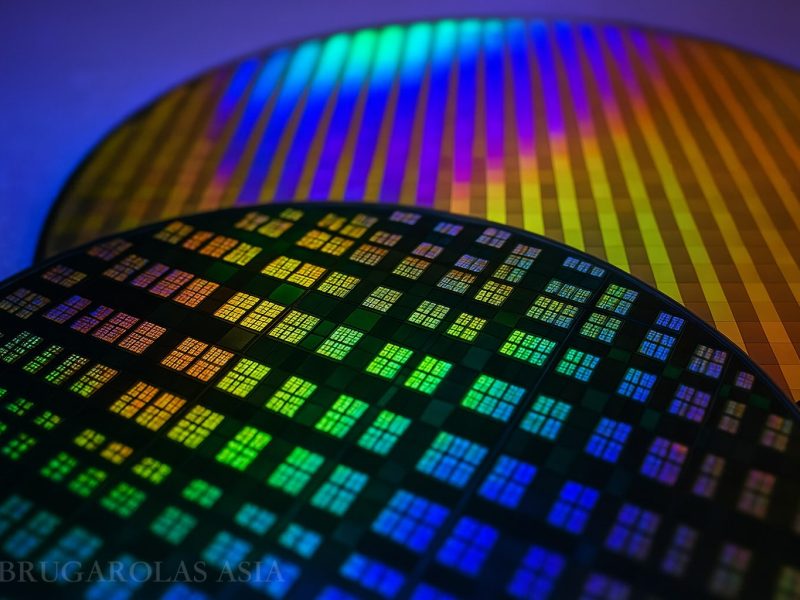

Common applications such as 5G, artificial intelligence (AI), IoT, EV, networked medical devices, industrial robots, and robot arm lubrication often require faster processing speeds and lower power consumption. This demands more complex manufacturing processes. Many processes today require manufacturing precision comparable to advanced processes, resulting in higher demands. Even the smallest impurities can lead to poor quality and reduced yield. These systems must operate reliably to meet these demands.

Specialty lubricants can significantly enhance the functionality of manufacturing and processing equipment, but using the wrong lubricant can lead to unexpected downtime and contamination, incurring high maintenance and downtime costs. Specialized lubricants prevent friction and wear, prolonging the lifespan of components and ensuring reliable system operation. The release of oil and particles from lubricants can contaminate wafer fab equipment and products, negatively impacting product quality and yield. To avoid these issues, choosing high-performance specialized lubricants with low emissions and low particle generation characteristics is crucial.

Semiconductor manufacturing and electronics processing equipment often operate under high temperatures and vacuum conditions, requiring high-performance lubricants to protect linear guides, bearings, ball screws, lead screws, seals to prevent wear.

Brugarolas Industrial Solutions

| BRUGAROLAS Grease | Performance | Specs | |||

|---|---|---|---|---|---|

| description | lube point | temp.(°C) | NSF H1 no. | color | |

| G.BESLUX FLUOR H-2 | White perfluorinated grease, formulated from medical-grade perfluoropolyether. Specifically resistant to oxidation, chemical agents, and high temperatures. | Gear, bearing, screw, turbine worm gear, slideway | -30~260(280) | 136455 | White |

| G.BESLUX FLUOR FG-222 | White perfluorinated grease, formulated from perfluoropolyether. Specifically resistant to oxidation, chemical agents, and high temperatures. | Gear, bearing, screw, turbine worm gear, slideway | -40~260(280) | N.A. | White |

| G.BESLUX FLUOR HT-2 | White perfluorinated grease, formulated from medical-grade perfluoropolyether. Specifically resistant to oxidation, chemical agents, and high temperatures. | Gear, bearing, screw, turbine worm gear, slideway | -40~280(300) | 136454 | White |

Typical Equipment

| Application | Brugarolas Solutions | Performance |

|---|---|---|

| Bearing | G.BESLUX FLUOR H-2 | Superior protection to bearing. Longlife. Synthetic PTFE grease. |

| Bearing | G.BESLUX FLUOR FG-152 | Superior protection to bearing. Longlife. Synthetic PTFE grease. |

| Conductive grease | G.BESLUX ANTI-SEIZE PASTE | Good conductive properties. Lubricating paste. Solid additives. |

| Joint | G.BESLUX TRIBOPASTE L-2/3 S | Synthetic lubricating paste. Prevents seizing of screws and bolts, facilitates disassembly |

| Electric motor | G.BESLUX SULPLEX M-2 PLUS | Special grease for electric motors |

| Electric motor | G.BESLUX KOMPLEX ALFA II | Synthetic grease for electric motors, longspan |

| Chain | BESLUX CHAIN 3020 ATOX | Synthetic chain oil. Low odor and smell. |

| Hinge | G.BESLUX LIPLEX ZST | Advanced Lithium high performance grease. Suitable for assembly usage and hinge function. |

| Compressor | BESLUX AIR-ATOX range | Synthetic compressor oil. Suitable for screw compressors. |

| Vacuum pump | BESLUX VAC 100 | High performance vacuum pump oil, ISO VG 100 |

| Vacuum pump | BESLUX VAC 68 | High performance vacuum pump oil, ISO VG 68 |

Our Innovations

BESLUXLUBE SMART LUBRICATION SYSTEM

On-site equipment, typically situated in specialized locations such as hard-to-achieve position or automated production line, is large in scale and requires a substantial amount of lubricant to ensure smooth operation. Maintaining these machines can be particularly challenging due to the frequency and unattended site (automated production line) . With the BESLUX range of lubricants, you can ensure that the equipment is adequately lubricated. Furthermore, the BESLUXLUBE smart lubrication system plays a vital role in enhancing workplace safety, preventing oil shortages, and extending the lifespan of the equipment.

By using our latest model BESLUXLUBE, you can ensure sufficient lubrication at every lubrication point. Simply set it through the touch panel, with precise control of lubrication volume down to 0.5ml per point. It also detects potential blockages in bearings and supports mobile remote alerts for low oil levels (optional feature).