Differences between Fluorine, PFAS, and PFOA/PFOS

Fluorine (F) is a highly reactive non-metallic element in the periodic table. Its hazards vary significantly depending on its form: elemental fluorine is a highly toxic yellow-green gas that can damage the respiratory system and be life-threatening even at low concentrations. Inorganic fluorides such as hydrogen fluoride (HF), calcium fluoride (CaF₂), and sodium fluoride (NaF) differ in toxicity depending on their solubility—for example, naturally occurring CaF₂ has low toxicity, while soluble fluoride salts in high doses can interfere with enzyme systems and damage bones and teeth. Low concentrations of fluoride in the environment or drinking water may help prevent dental caries (e.g., in toothpaste), but excessive intake can lead to dental fluorosis or skeletal fluorosis. Therefore, fluorine itself cannot be simply labeled as “harmful” or “harmless”; its impact depends on its chemical form, concentration, and exposure pathway.

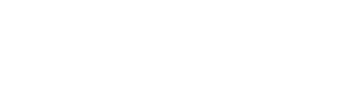

PFAS (per- and polyfluoroalkyl substances) are a large group of synthetic chemicals composed of carbon and fluorine, known for their extreme stability and resistance to degradation. They are widely used in waterproof, oil-repellent, stain-resistant, and high-temperature-resistant products. PFOA (perfluorooctanoic acid) and PFOS (perfluorooctane sulfonic acid) are two representative members of the PFAS family. Due to their persistence, bioaccumulation, and potential risks to human health and the environment, they have been strictly regulated or banned in many countries.

Because of its unique properties, fluorine is extensively applied in modern industry and consumer products where performance demands are critical, such as electronics, semiconductors, and automotive manufacturing. Common applications include non-stick cookware coatings, water- and stain-repellent textiles, food packaging, firefighting foams, advanced wafer fabrication (cleanrooms), motors, computers, and many other products.

What are the problems with PFAS?

The use of PFAS also brings potential environmental and health risks. These substances are extremely resistant to degradation, bioaccumulative, and can enter natural water bodies through wastewater discharge. If not properly managed, fluorinated compounds can further contaminate soil and groundwater, posing threats to ecosystems and human health. PFAS may interfere with the human endocrine system and have been linked to various health concerns, including cancer, immune system impairment, and reproductive issues. For these reasons, per- and polyfluoroalkyl substances (PFAS) are gradually being phased out.

As global awareness of PFAS’s environmental impact increases, many countries and regions have strengthened regulations on these compounds. The U.S. Environmental Protection Agency (EPA) has listed perfluorooctane sulfonic acid (PFOS), perfluorooctanoic acid (PFOA), and their derivatives under the Toxic Substances Control Act, requiring reduced use in industrial processes and the search for alternatives. The European Union, through the Stockholm Convention, has imposed strict restrictions on the use of various PFAS substances to mitigate their environmental and health impacts. These regulatory measures are driving industries—led by the electronics sector—to seek fluorine-free alternatives and more environmentally friendly lubricant formulations.

Why is PFAS used in lubricant formulations?

Fluorinated lubricants that contain PFAS (Per- and Polyfluoroalkyl Substances) are renowned for their outstanding performance under extreme conditions where high wear resistance, thermal stability, and chemical inertness are required. While not always necessary, in certain lubrication points these properties are critical, making PFAS-based additives or base oils valuable in lubricant formulations.

Does PTFE belong to Fluorine, PFAS, or PFOA/PFOS?

PTFE (commonly known as Teflon, polytetrafluoroethylene, or “the king of plastics”) is a type of PFAS. PFAS are fluorine–carbon-based substances characterized by strong C–F bonds, giving them high stability, hydrophobicity, and oleophobicity. PTFE is a polymer with a fully fluorinated carbon backbone, classified as a long-chain PFAS. It exhibits exceptional heat resistance, low friction, and chemical inertness, which is why it is widely used in non-stick cookware, seals, and electrical insulation.

Although PTFE itself is insoluble and not bioaccumulative, its production historically involved other PFAS substances such as PFOA, which has since been banned in many countries due to its persistence and toxicity. For this reason, PTFE is often mentioned in PFAS-related discussions, not because PTFE is inherently toxic, but because of its manufacturing connection to restricted PFAS compounds.

Alternatives: Fluorine-Free and PFAS Products, and PFAS-FREE

Although “PFAS-FREE” does not necessarily mean “fluorine-free,” some industry-leading companies have already required their suppliers to adopt fluorine-free solutions in order to eliminate regulatory uncertainty in the future.

When discussing PFAS specifically, the potential environmental and health hazards have led some countries and regions to restrict and regulate their use, while certain companies have also limited fluorine-based products. For example, the EU and the United States have already banned or restricted certain PFAS chemicals. At the same time, our R&D laboratories and partner companies are actively searching for and developing safer alternatives to reduce dependence on PFAS.

From past experience, using PFAS-free lubricants is not a new concept; however, replicating the unique chemical performance of PFPE and PTFE without PFAS materials remains a challenge. Nevertheless, Brugarolas has continuously developed and launched PFAS-FREE high-performance lubricant alternatives as part of our product line.

In short, PFAS are important industrial chemicals but carry environmental and health risks. Effective management and the development of alternatives are the key directions for ongoing research and innovation.

Brugarolas S.A.

Founded in 1885 and headquartered in Barcelona, Spain, Brugarolas Lubricants is dedicated to innovation in lubricant applications. All products comply with the RoHS directive, ensuring import and export without concerns over restricted substance testing. Our solutions extend equipment lifetime and reduce operating costs. With a full product line covering a wide range of industries—including cement, mining, food, paper, aerospace, and advanced electronics—if you require specialized lubrication products not listed below, contact our engineers with hesitation.

Our Advantages:

- Reduce friction and wear, minimize abnormal noise

- Extend component lifetime

- Prevent contamination

- Enhance functionality and reliability

- Improve production yield

- Avoid product defects

- Increase uptime

- Low odor

- Safe for operators

- Non-hazardous

- Lower overall costs

- RoHS and REACH/SVHC compliant

- PFAS free

- MOSH/MOAH free

- Biodegradable