Cement industry

Specialty Lubricants in

CEMENT INDUSTRY

The cement industry is one of the core sectors in modern construction and infrastructure development. Cement is a key component of building materials, widely used in construction, bridges, roads, and other civil engineering projects.

In cement plants, from raw materials to the final stages, the main processes include the mining workshop, raw material workshop, clinker workshop, and finishing workshop. Each stage has its own objectives and therefore utilizes different equipment, such as rotary kilns, mills, roller presses, and more.

Common equipments:

Rotary Kiln (Open Gear), Ball Mill, Vertical Roller Mill, Roller Press, Crusher, Conveyor System, Preheater, Cooler, Dust Collector, Separator, Bucket Elevator, Homogenizing Silo, Clinker Silo, Cement Silo, Grinding Mill, Raw Mill, Coal Mill, Fan and Blower, Hydraulic System.

With Brugarolas’ high-performance greases, the lifespan of equipment is significantly optimized, minimizing breakdowns and machine downtime for maintenance purposes.

Only by selecting appropriate lubrication procedures, suitable lubricants, proper lubrication methods, and conducting regular on-site inspections based on the actual operating conditions of the equipment can the safe operation of gears be effectively ensured. This product series has been recognized and recommended by equipment manufacturers such as KHD Humboldt Wedag, Polysius, Metso Outotec, F.L. Smidth, CITIC HMC (CITIC Heavy Industries), and Northern Heavy Industries Group.

Brugarolas Industrial Solutions

Roller Press, Crusher, Cooler

| Application | Brugarolas Solutions | Performance |

|---|---|---|

| Main Bearing | G.BESLUX PLEX EH-1/G | Resistance to heavy loads, impact loads |

| Main Bearing | G.BESLUX PLEX EH-2/G | Resistance to heavy loads, impact loads |

| Hydraulic System | FLUID DRIVE HM-46 | High performance hydraulic oil, ISO VG 46 |

| Hydraulic System | FLUID DRIVE HM-68 | High performance hydraulic oil, ISO VG 68 |

| Main Reducer Planetary Gearbox | BESLUX GEAR XP 320 | High performance gear oil, ISO VG 320 |

| Main Reducer Planetary Gearbox | BESLUX GEAR ET 220/320 | High performance special gear oil with tacky, red color |

| Main Reducer Planetary Gearbox | BESLUX GEARSYNT 320 | Synthetic gear oil, ISO VG 320 |

| Universal Coupling | G.BESLUX SULPLEX EH-1/G | Resistance to heavy loads, impact loads with solids additives |

| Universal Coupling | G.BESLUX GFG | Resistance to heavy loads, impact loads with solids additives |

| Main Motor Bearing | G.A. PLEX 2 | Special lubricants for electric motor |

| Main Motor Bearing | G.BESLUX KOMPLEX ALFA II | Special synthetic lubricants for electric motor |

| Rotary Joint | G.A. PLEX 2 | Special lubricants for joints |

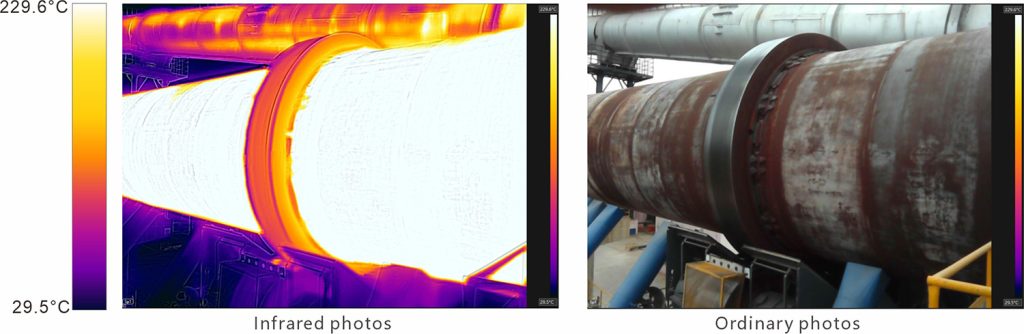

Open Gear (Kiln, Mill, Crusher)

Various factors can lead to poor meshing of open gears, causing issues such as surface abrasion, galling, pitting, and spalling, ultimately shortening the lifespan of the gears. In grinding systems, open gears may suffer from premature failure due to excessive impact loads, vibrations in the transmission system, and the harsh dust-filled environment.

Therefore, lubrication of open gears in cement plants requires special attention. Understanding proper lubrication should start from the gear installation process. BRUGAROLAS BESLUX CROWN, backed by decades of experience, has developed a comprehensive lubrication process for open gears.

During the normal lubrication phase, the selection of an appropriate adhesive lubricant (such as high-viscosity pure oil or fluid grease) should be based on factors like gear power, temperature variations, and environmental conditions. These lubricants must have suitable viscosity (adapted to equipment size, lubrication method, and temperature) and provide sufficient extreme pressure (EP) performance (e.g., four-ball welding load above 800 kg). Additionally, lubricants containing a proportion of solid additives are a better choice as they help meet extra load-bearing demands and offer emergency protection.

To ensure the safe operation of gears, it is essential to select the proper lubrication steps, appropriate lubricants, and correct lubrication methods while performing regular on-site inspections based on actual operating conditions. This product line has been recognized and recommended by numerous OEMs. Please contact your local distributor for more details.

| Application | Brugarolas Solutions | Performance |

|---|---|---|

| Ball mill (Open gear) | G.BESLUX CROWN H-00/R | Grease-type open-gear lubricant, 4 ball EP test>800kg |

| Ball mill (Open gear) | G.BESLUX CROWN M FLUID/PLUS | Grease-type open-gear lubricant, 4 ball EP test>801kg |

| Ball mill (Open gear) | G.BESLUX CROWN H-3000 | Grease-type open-gear lubricant, 4 ball EP test>802kg |

| Ball mill (Open gear) | G.BESLUX CROWN H-6000 | Grease-type open-gear lubricant, 4 ball EP test>803kg |

| Ball mill (Open gear) | G.BESLUX CROWN HEAVY MILL | Grease-type open-gear lubricant, 4 ball EP test>804kg |

| Ball mill (Open gear) | G.BESLUX CROWN HEAVY MILL PLUS II | Grease-type open-gear lubricant, 4 ball EP test>800kg |

| Ball mill (Open gear) | BESLUX CROWN 150 OG PLUS | High viscosity oil-type lubricant for extreme pressure, 4 ball EP test>800kg |

| Ball mill (Open gear) | BESLUX CROWN 320 OG PLUS | High viscosity oil-type lubricant for extreme pressure, 4 ball EP test>800kg |

| Ball mill (Open gear) | BESLUX CROWN 500 OG PLUS | High viscosity oil-type lubricant for extreme pressure, 4 ball EP test>800kg |

| Ball mill (Open gear) | BESLUX CROWN 1000 OG PLUS | High viscosity oil-type lubricant for extreme pressure, 4 ball EP test>800kg |

| Ball mill (Open gear) | G.BESLUX WHITE OG-320 | High viscosity white oil-type lubricant for extreme pressure, 4 ball EP test>800kg |

| Ball mill (Open gear) | G.BESLUX WHITE OG-680 | High viscosity white oil-type lubricant for extreme pressure, 4 ball EP test>800kg |

| Supporting bearing | BESLUX SINTER 1500 CH | High resistance to heavy loads, impact loads |

| Supporting bearing | BESLUX GRAFOL 320 | Synthetic oil, High resistance to heavy loads, impact loads |

| Vertical mill | BESLUX GEAR XP 320 | Micro-pitting protection gear oil, Resistance to heavy loads |

| Vertical mill | BESLUX GEARSYNT 320 | Micro-pitting protection synthetic gear oil, Resistance to heavy loads |

G. BESLUX CROWN – Graphite Fluid Grease OG Type

| Product | G. BESLUX RPR PLUS (Online Repair) | G.BESLUX CROWN H-1/R | G.BESLUX CROWN H-00/R | G.BESLUX CROWN R FLUID | G.BESLUX CROWN H-0 PLUS | G.BESLUX CROWN L FLUID | G.BESLUX CROWN EL FLUID |

|---|---|---|---|---|---|---|---|

| Color | Ivory | Black | Black | Black | Black | Black | Black |

| Base Oil | Mineral | Mineral | Mineral | Mineral | Synthetic | Synthetic | Synthetic |

| Thickener | Lithium | Aluminium complex | Aluminium complex | Aluminium complex | Aluminium complex | Aluminium complex | Aluminium complex |

| NLGI Grade | 2 | 1 | 0 | 0 | 0 | 0 | 0 |

| Drop Point | >180°C | >190°C | >190°C | >190°C | >190°C | >200°C | >200°C |

| Welding Load | N.D. | >800Kg | >800Kg | >800Kg | >800Kg | >800Kg | >800Kg |

| FZG A/S Test | N.D. | >12 | >12 | >12 | >12 | >12 | >12 |

| Solid Additives | Special solid additives | Graphite | Graphite | Graphite | Graphite | Graphite | Graphite |

| Working Temp. | N.D. | -15~130 | -10~150 | -15~130 | -10~140 | -15~130 | -18~130 |

| Product | G.BESLUX CROWN M FLUID | G.BESLUX CROWN M FLUID PLUS | G.BESLUX CROWN H-3000 | G.BESLUX CROWN H-6000 | G.BESLUX CROWN HEAVY MILL | G.BESLUX HEAVY MILL PLUS II |

|---|---|---|---|---|---|---|

| Color | Black | Black | Black | Black | Black | Black |

| Base Oil | Synthetic | Synthetic | Synthetic | Synthetic | Synthetic | Synthetic |

| Thickener | Aluminium complex | Aluminium complex | Aluminium complex | Aluminium complex | Aluminium complex | Aluminium complex |

| NLGI Grade | 0 | 0 | 0 | 00/000 | 0 | 0 |

| Drop Point | >200°C | >200°C | >200°C | >200°C | >200°C | >200°C |

| Welding Load | >800Kg | >800Kg | >800Kg | >800Kg | >800Kg | >800Kg |

| FZG A/S Test | >12 | >12 | >12 | >12 | >12 | >12 |

| Solid Additives | Graphite | Special graphite | Graphite | Graphite | Graphite | Graphite |

| Working Temp. | -15~130 | -15~130 | -10~150 | 0~150 | 0~150 | 5~120 (short 140) |

BESLUX CROWN OG PLUS Neat Oil OG Type

| Product | BESLUX CROWN 150 OG PLUS | BESLUX CROWN 320 OG PLUS | BESLUX CROWN 500 OG PLUS | BESLUX CROWN 1000 OG PLUS | BESLUX CROWN 1200 OG PLUS | G. BESLUX WHITE OG-320 | G. BESLUX WHITE OG-680 |

|---|---|---|---|---|---|---|---|

| Color | Light brown | Light brown | Light yellow | Light yellow | Light yellow | Beige | Beige |

| Base Oil | Synthetic | Synthetic | Synthetic | Synthetic | Synthetic | Synthetic | Synthetic |

| NLGI Grade | N.D. | N.D. | N.D. | N.D. | N.D. | 0 | 0 |

| Drop Point | >220°C | >220°C | >220°C | >220°C | >220°C | >200°C | >200°C |

| Welding Load | >800Kg | >800Kg | >800Kg | >800Kg | >800Kg | >800Kg | >800Kg |

| FZG A/S Test | >12 | >12 | >12 | >12 | >12 | >12 | >12 |

| Solid Additives | N.D. | N.D. | N.D. | N.D. | N.D. | White solids | White solids |

| Working Temp. | 15 ~ 120 | 15 ~ 120 | 15 ~ 120 | 15 ~ 120 | 15 ~ 120 | 15 ~ 120 | 15 ~ 120 |

* The above data are typical laboratory data, and each batch is subject to the oil analysis report.

* NLGI 000 grade products are recommended for immersion lubrication.

We have over 20 years of on-site experience across multiple countries, including South America, Africa, and Southeast Asia. Our products are applied to industry-leading large-scale equipment such as Caterpillar, Komatsu, Shougang, and Bucyrus.

Brugarolas has also obtained certifications from various OEM equipment manufacturers and continues to drive the development of biodegradable, environmentally friendly high-performance lubricants.

Typical Equipment

| Application | Brugarolas Solutions | Performance |

|---|---|---|

| Wire rope | G.BESLUX KBL | Superior protection to wire rope with penetration, black color |

| Wire rope | G.BESLUX SULPLEX ROPE-00 | Superior protection to wire rope with penetration |

| Wire rope | G.BESLUX ECOCABLE | New generation biodegradable wire rope lubricant |

| Screw | G.BESLUX ANTI-SEIZE PASTE-1 | Paste. Prevents seizing of screws and bolts, facilitates disassembly |

| Electric motor | G.BESLUX SULPLEX M-2 PLUS | Special grease for electric motors |

| Electric motor | G.BESLUX KOMPLEX ALFA II | Synthetic grease for electric motors, long-life |

| Gear coupling | G.BESLUX SULPLEX EH-1/G | Protects internal and external gear surfaces of couplings, good pumpability |

| Roller bearing | G.BESLUX PLEX H-1/KT | Continuous drilling, drill rods |

| Roller bearing | G.BESLUX PLEX H-2/KT | Continuous drilling, drill rods |

| Crusher | G.BESLUX SULPLEX EH-2 PLUS | High resistance to heavy loads, anti-corrosion |

| Crusher | G.BESLUX SULPLEX EH-1/G | High resistance to heavy loads, impact loads |

Our Innovations

BESLUXLUBE SMART LUBRICATION SYSTEM

Cement equipment, typically situated in specialized locations such as high position or long distance, is large in scale and requires a substantial amount of lubricant to ensure smooth operation. Maintaining these machines can be particularly challenging due to their size and the harsh environmental conditions they are exposed to. With the BESLUX range of lubricants, you can ensure that the equipment is adequately lubricated. Furthermore, the BESLUXLUBE smart lubrication system plays a vital role in enhancing workplace safety, preventing oil shortages, and extending the lifespan of the equipment.

By using our latest model BESLUXLUBE, you can ensure sufficient lubrication at every lubrication point. Simply set it through the touch panel, with precise control of lubrication volume down to 0.5ml per point. It also detects potential blockages in bearings and supports mobile remote alerts for low oil levels (optional feature).